trees saved per year through factory energy efficiencies (2016-2020)

- 2018-Present

- Status: On-track

Project overview

Continuing our partnership with German development agency GIZ and KTDA to deliver climate change and energy efficiency initiatives in Kenyan tea.

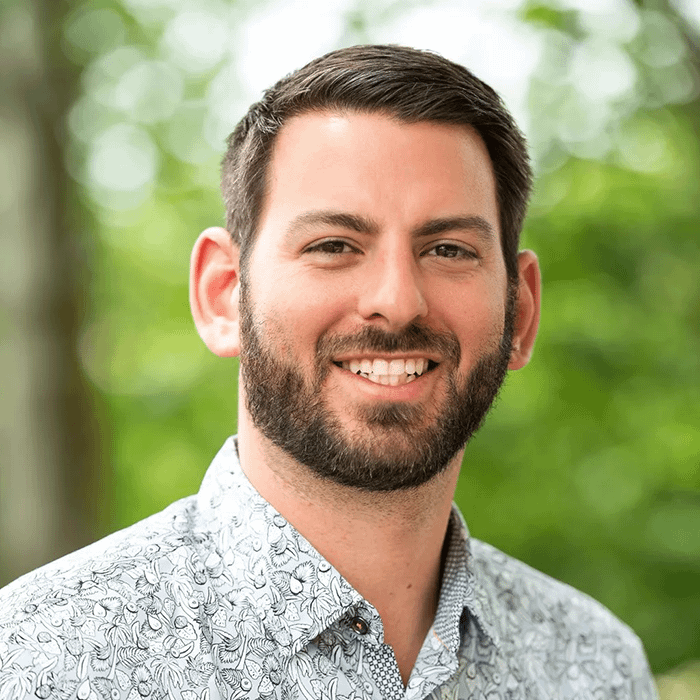

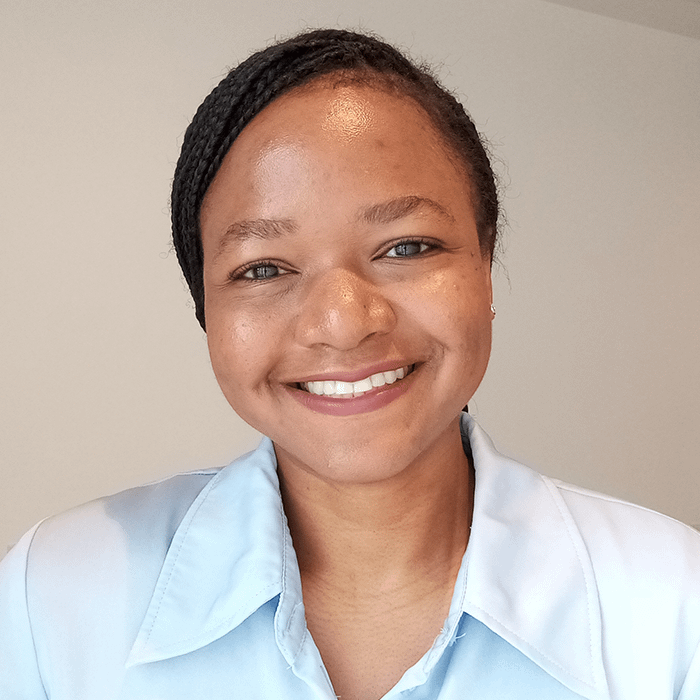

Project partners

BMZ (Fund for Trilateral Cooperation with Asia) and Ministry of Agriculture and Rural Affairs of China (MARA) implemented through FAO and the Chinese Academy of Agricultural Sciences (CAAS), supporting GIZ and the UN Food and Agricultural Organisation (FAO) Kenya.